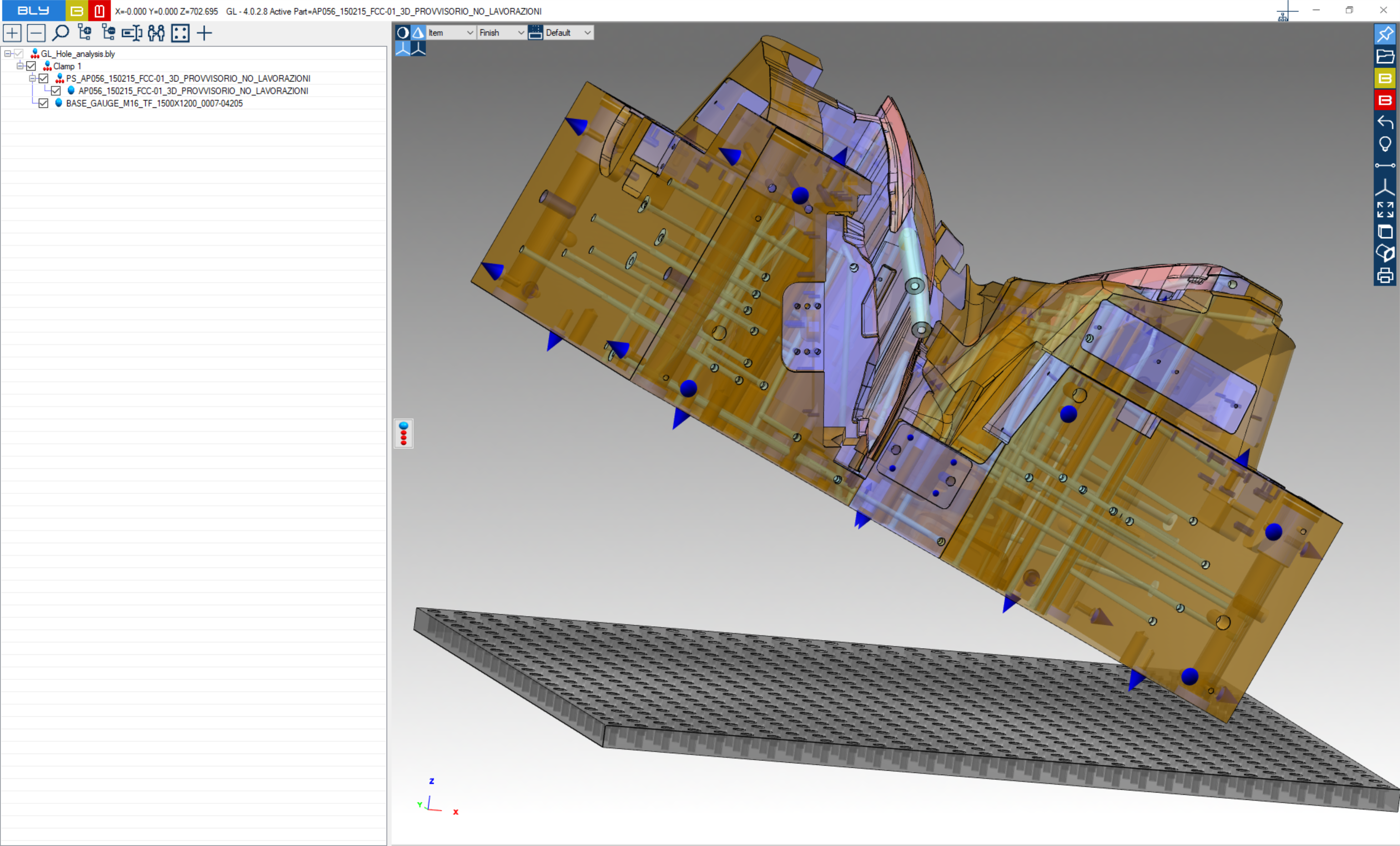

PHASE 2: Workpiece Orientation

As opposite as Phase 1, machine setup does not give you the possibility to freely orient the workpiece, but forces the orientations defined by the placement seats already present in the workpiece. The cones represent the FCS System holes and drive the job's orientation. Any other placement is not acceptable, since has not been evaluated and approved.

Watch an example in this VIDEO

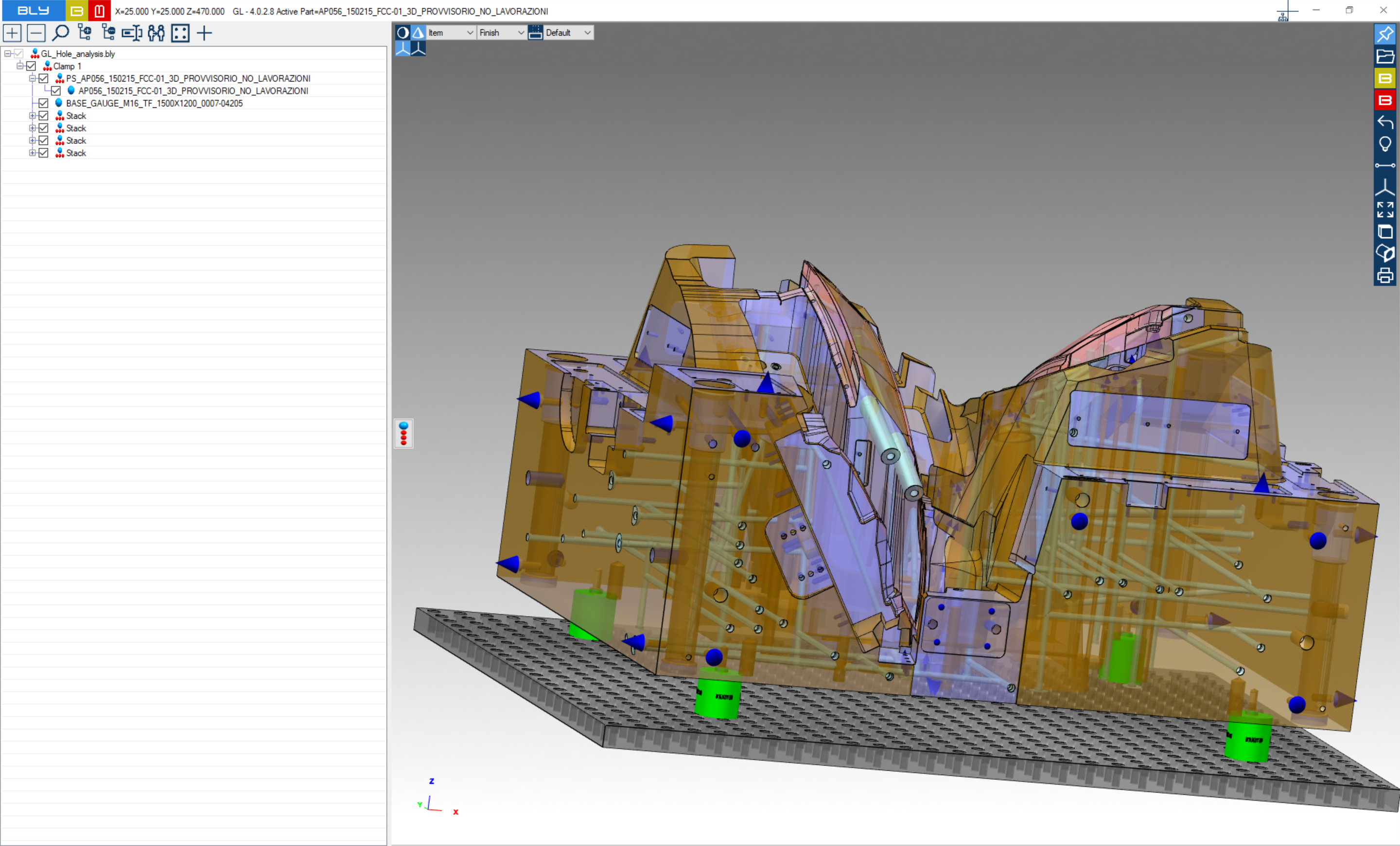

Independently form the starting orientation, clicking on one of the cones will place the job on the table with all the (possible) stacks applied

Position can then be adjusted by dragging the piece or using the orientation option (see Phase 1: Workpiece orientation), with the limitation that at this stage the job will snap to the grid, simulating the real workpiece placement onto a machine. Naturally, inclination cannot be changed: seats' orientation drives the workpiece position and if the user tries to tilt it, Guideline returns it back to the previous position.