Guideline-NX interoperability #1: ON-LINE

This is the most straightforward option to exchange data between Guideline and NX: it requires to have both sw installed and licensed on the same PC. Both licenses will be used for the entire clamping definition process, which at the end will be automatically transferred to NX.

This procedure can be used with NX assemblies having at least one workpiece as component. Stock part is optional.

N.B: workpiece MUST be a component, no geometry can be selected from the NX work part.

Procedure: Workpiece and stock selection

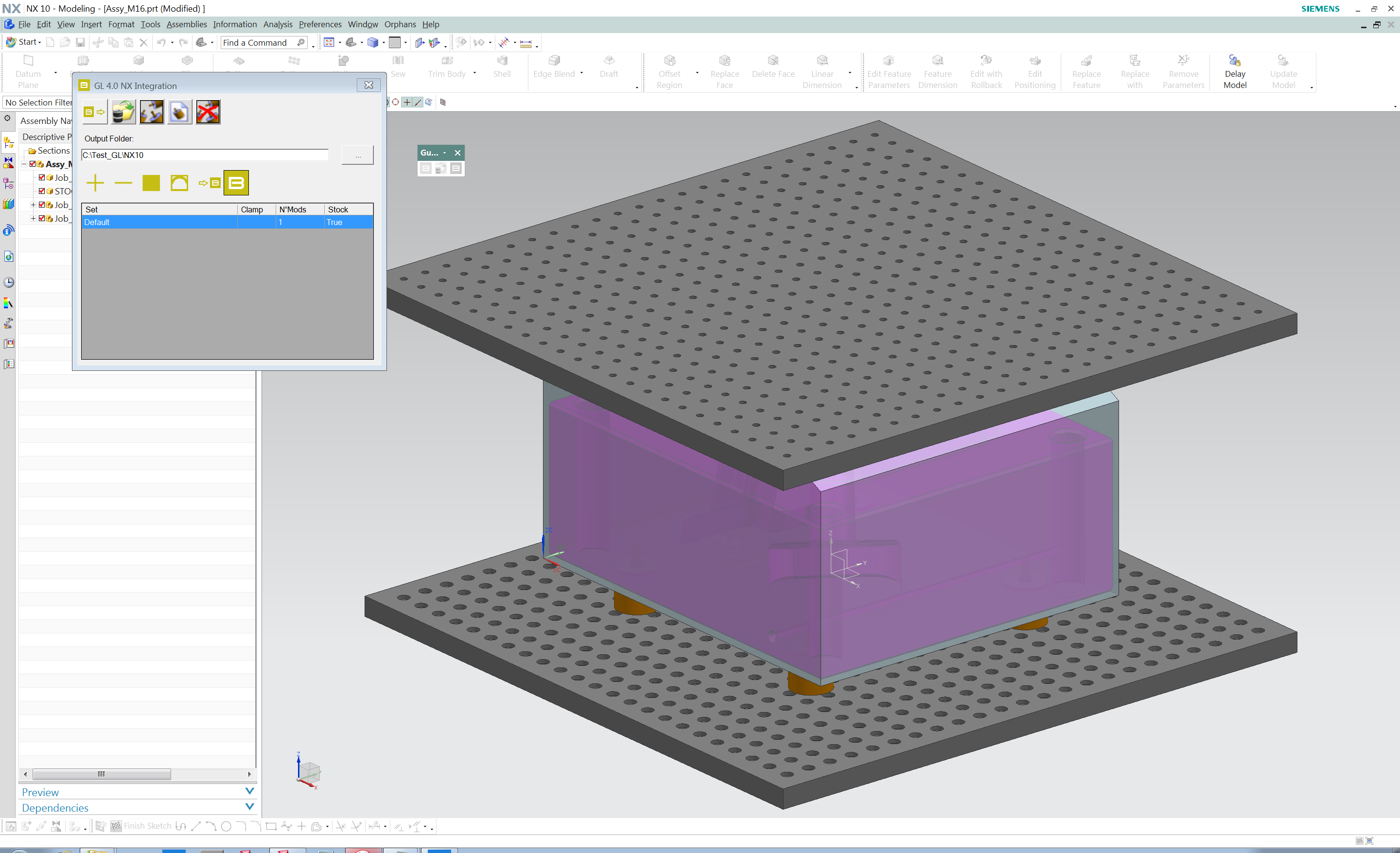

In NX, open the assembly containing the workpiece to be clamped and from Guideline toolbar launch Guideline integration: the GL 4.0 NX Integration window will pop-up.

Several "Sets" (called "PS") of workpiece + raw block can be defined and clamped.

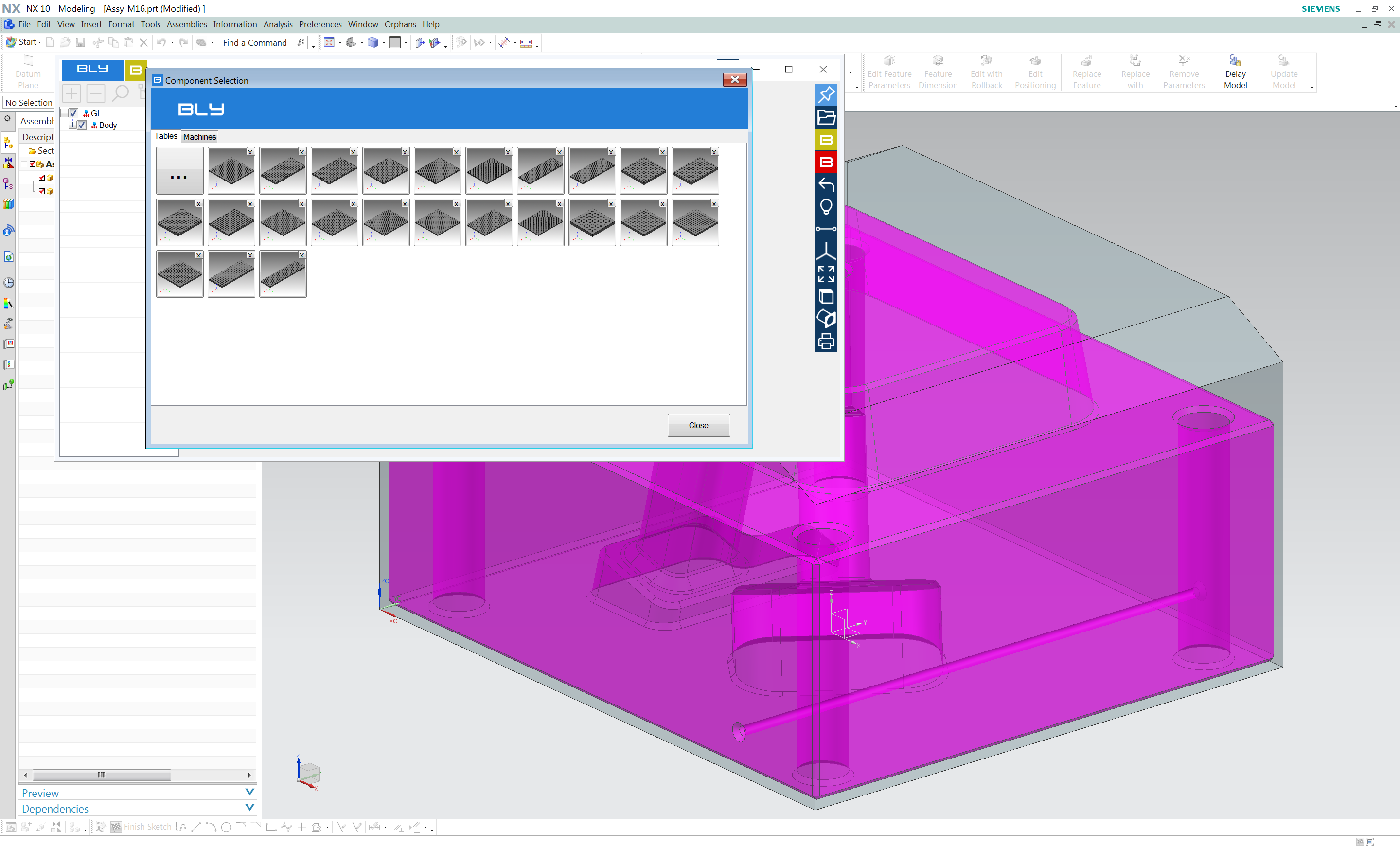

- Click "Select Workpiece(S)" to open the selection window and select the workpiece(s) to clamp. Multiple bodies can be selected and transferred to Guideline;

- If present, click "Select Stock" to open the selection window and select the stock to clamp. Only one raw body each set can be selected and transferred to Guideline;

- OPTIONAL: specify the Reference Set to be used via "Specified Reference Set" dropdown menu. This will apply to the clamping sub-assembly(ies) created from Guideline;

- The PS defined will be listed into "Defined PS" list. It is possible to define as many PS as needed;

- Select from the list the PS that you want to clamp together;

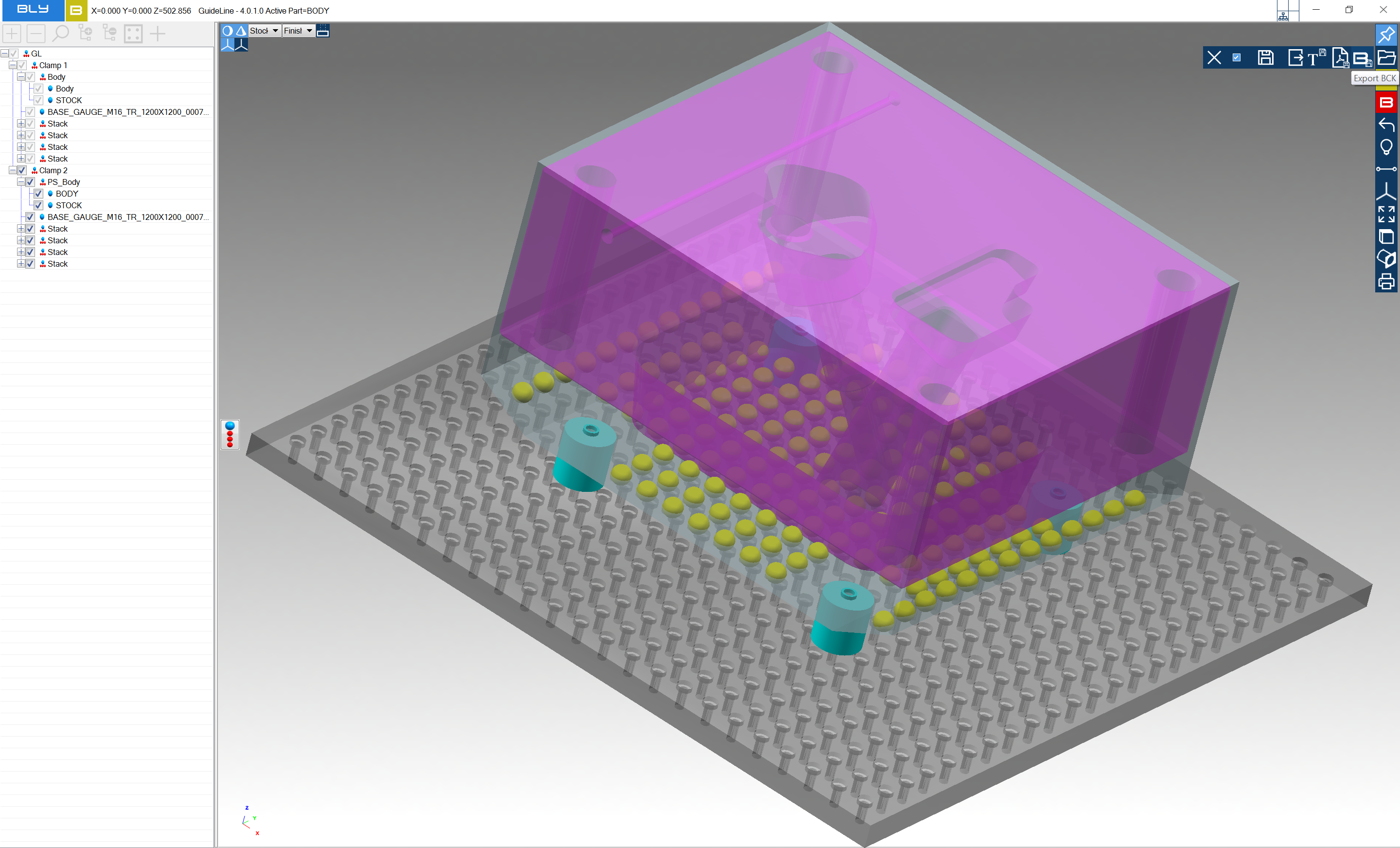

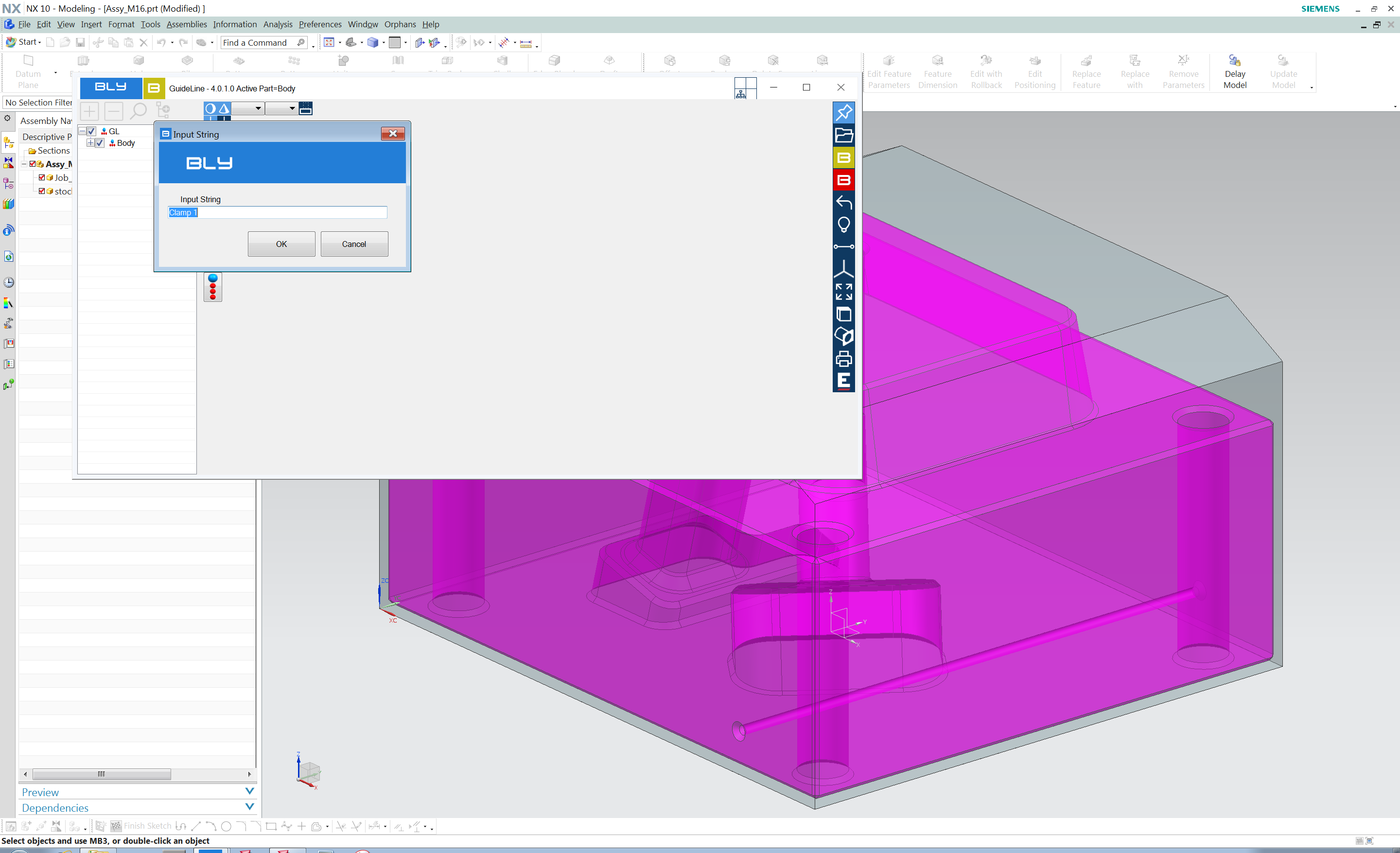

- Press "Open sets clamp in GL": The selected PS will be converted to Bly format and saved into a subfolder called "PS" under Output Folder. Guideline 4.0 will then be launched and will ask to open a bly file:

- selecting an existing bly file will open it and the PS will be added to the existing clamps;

- giving a new name, a new bly file will be created with the specified PS added, ready for clamping,

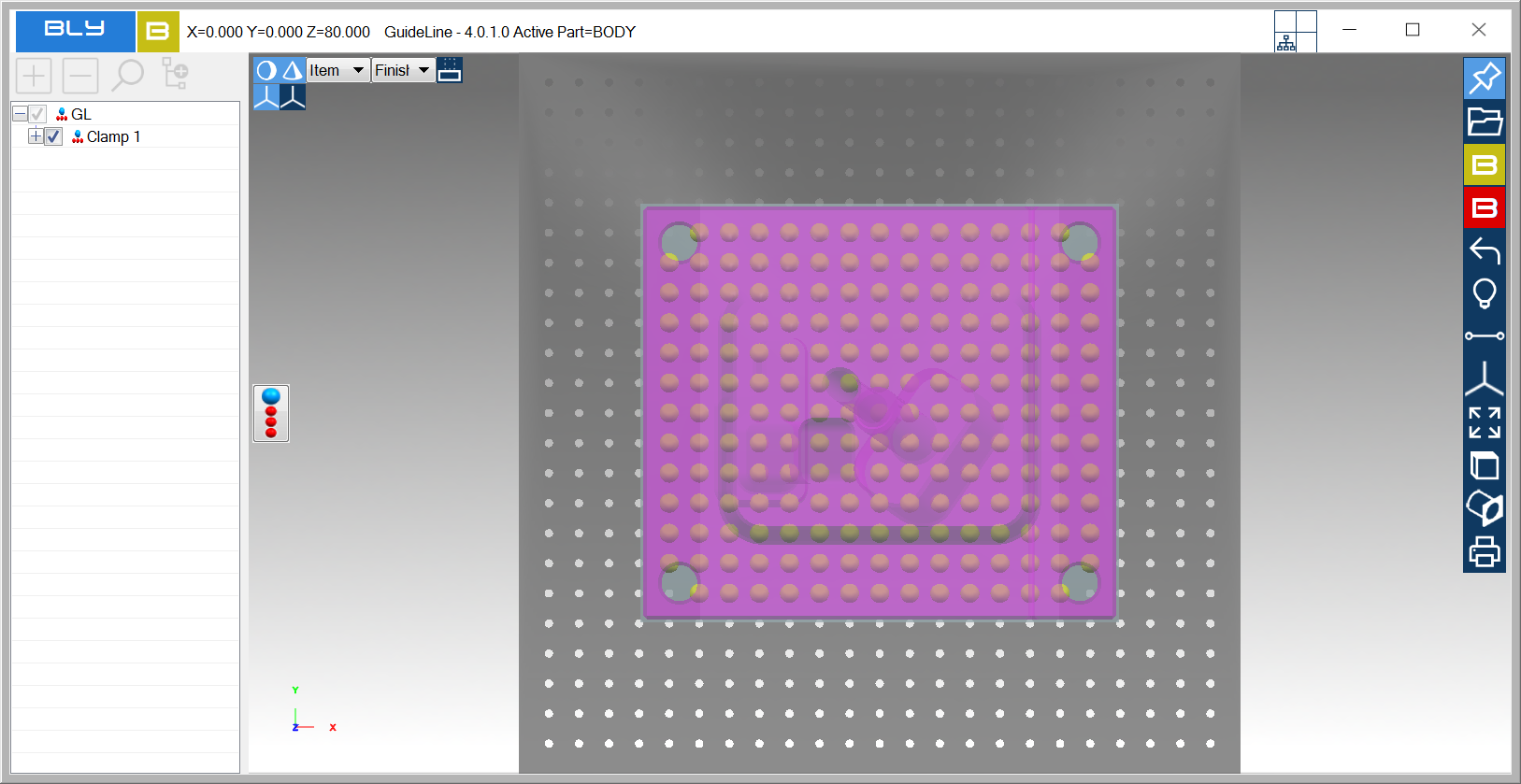

Once opened, Guideline 4.0 will proceed as usual, asking for a new clamp or opening the existing one

Clamp can be then defined as usual using Guideline's functionalities. There is no limitation in the number of clamps and it is possible to clamp the stock: if the stock is not imported from NX, it can be created within Guideline (see Stock Creation/Import) and then exported back in NX.

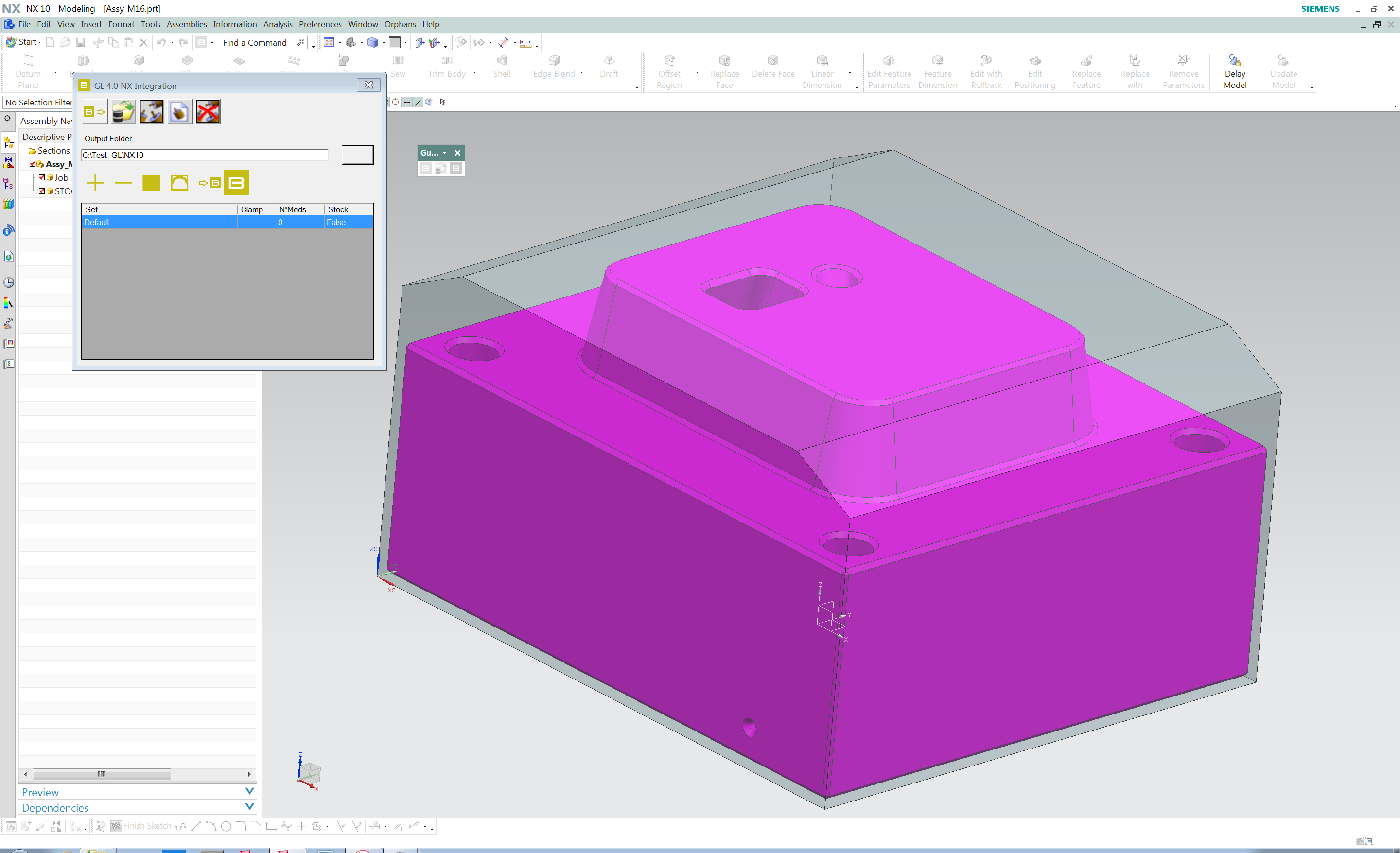

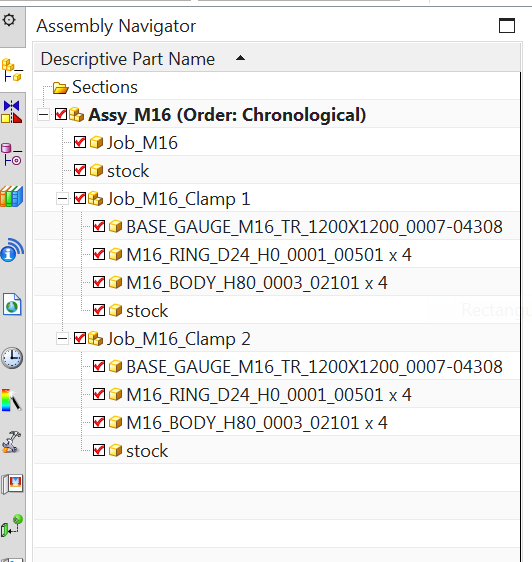

To export the clamp(s) back to NX, select "Export BCK" form the main Guideline's toolbar: clamp(s) will be exported back to NX as sub-assembly of the work part. FCS components are loaded from Guideline's library and added as component of the clamp subassembly(ies).

Clamp(s) are exported respecting the original workpiece CSYS, so their components are positioned "around" the workpiece: this will recreate the correct relative positioning.

As already specified, all subassembly components are NX components, so all the NX assembly functionalities will be available and effective (Reference Sets, layers, opening etc.)

Once clamps have been added to NX assembly, Guideline can then create seats (see Create subtraction (FCS Seats))